Understanding CAD CAM Milling Burs and Their Applications

What Is a CAD CAM Milling Bur and How Does It Work?

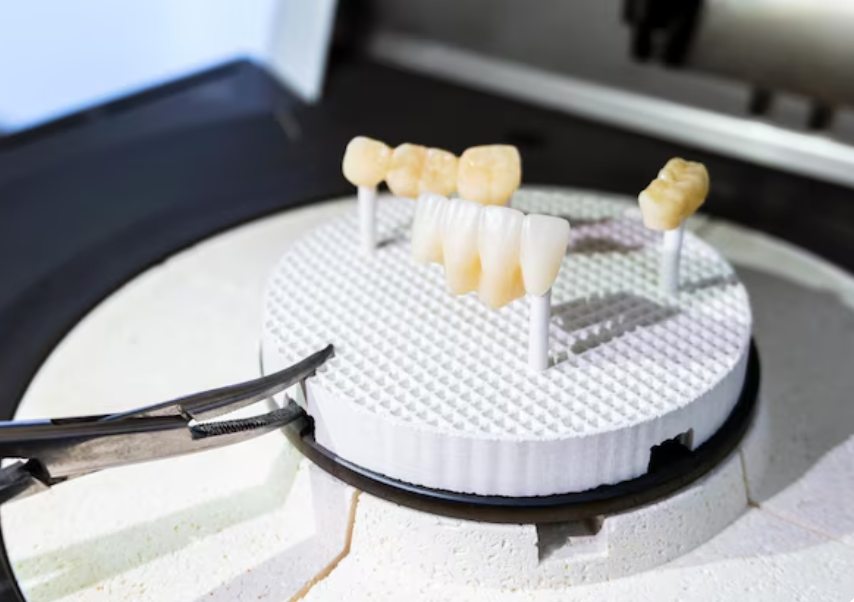

A CAD CAM milling bur is the sharp tool that does the actual cutting when a dental lab makes crowns or bridges with a milling machine. These burs sit inside the dental CAD/CAM setup. They turn digital designs into real restorations by shaving material off solid blocks—things like zirconia, glass ceramic, PMMA, or wax.

Milling burs are the cutting tools used in the CAM phase of the dental CAD/CAM process. They chip away at the block until the crown, bridge, or inlay matches the design perfectly. It all starts with a scan from an intraoral camera. The dentist or tech designs the piece in CAD software. Then the file goes to the mill. The machine picks the right burs and carves the shape step by step.

Big burs do the rough work fast. Smaller ones come in later for the fine details and smooth surfaces. Every bur has a job. Shape, length, and the way the edges are cut decide how clean and quick the job gets done.

Why Is the Material of a Milling Bur So Important?

What the bur is made of decides how well it cuts and how long it lasts. Tough stuff like carbide or diamond coating stays sharp longer and shakes less while working. Less shake means the crown fits better on the first try.

The material also fights wear. Diamond-coated ones keep their bite on super-hard zirconia. Use them wrong and they still wear out fast. You have to match the bur to the block material. Some work great on soft wax, others only shine on metal or ceramic.

Dental Milling Burs are general-purpose burs that can be used for a variety of dental materials, including ceramic, composite resin, and acrylic. Picking the right one saves money and keeps the mill running smooth.

Common Material Options for CAD CAM Milling Burs

What Are the Most Widely Used Materials for Milling Burs?

Tungsten Carbide Burs

Carbide is everywhere because it’s hard and tough. Labs love it for zirconia and metal jobs. Our milling bur usually adopts carbide or coating process, with high wear resistance and long service life. One good carbide bur can mill dozens of units before you notice it getting dull.

Diamond-Coated Burs

Real industrial diamond gets glued onto the bur. Nothing beats them on fully sintered zirconia or lithium disilicate. You get glass-smooth surfaces with almost no chips. However, burs with a fine grit or a special coating can produce a smoother surface finish, reducing the need for additional polishing. Push them too hard or run them dry and the diamond layer peels off quicker than you expect.

Ceramic Burs

Some burs are made from the same tough ceramic as the blocks. They don’t heat up much, so they’re perfect for wax or PMMA temporaries. No risk of melting or warping the plastic.

Stainless Steel Burs

Cheap and cheerful. Great for roughing out soft stuff or when you’re on a tight budget. They wear out fast compared to the fancy ones, but sometimes that’s all you need.

Comparing Material Performance Across Dental Applications

Which Bur Material Works Best for Different Dental Materials?

For Zirconia Blocks

Zirconia is rock-hard. Dental Zirconia Milling Bur are specifically designed for milling zirconia, a strong and durable dental material that is commonly used for crowns and bridges. Diamond-coated burs win here because they stay sharp long enough to finish the job clean.

For PMMA and Wax Models

Softer stuff doesn’t need the heavy artillery. Ceramic or even stainless steel gets the job done cheap. Our milling bur has wide cutting compatibility and is suitable for common dental materials such as zirconium, CrCo alloy, PMMA (polymethyl methacrylate), wax materials, etc. No point wasting diamond on plastic.

For Metal Frameworks (e.g., Titanium)

Carbide is king on titanium or chrome-cobalt. It holds an edge and doesn’t flex under pressure.

How Does Material Choice Affect Milling Accuracy and Surface Quality?

Harder burs vibrate less. Less vibration equals tighter margins. A good diamond coating leaves the surface so smooth you barely need to polish. Cheap or worn coating chips the edge and you spend extra time fixing it by hand.

Factors to Consider When Choosing a Milling Bur Material

What Should You Look for When Selecting a Bur Material?

Durability and Wear Resistance

A bur that lasts 150 units instead of 50 saves real money. Our milling bur is particularly suitable for small and medium-sized dental laboratories or users with limited budgets. Its versatility and reliability make it a popular choice in the field of dental processing.

Compatibility With Your Milling Machine Settings

Check your machine’s max RPM and coolant setup. Some burs hate dry milling, others can’t take full speed. Push the wrong combo and the bur snaps or burns up fast.

Cost-Efficiency Over Time

Steel is cheap today, expensive tomorrow because you keep buying more. Good carbide or diamond costs more up front but pays off over months.

Introduction to XANGTECH’s CAD CAM Milling Burs

Why Choose XANGTECH Milling Burs for Your Dental Lab Needs?

We make burs at XANGTECH that just work—sharp, tough, and fit almost every open milling machine out there.

High Performance Materials Used by XANGTECH

You pick carbide, diamond-coated, or ceramic depending on the job. Our milling bur has wide cutting compatibility and is suitable for common dental materials such as zirconium, CrCo alloy, PMMA (polymethyl methacrylate), wax materials, etc. One drawer holds everything your lab needs.

Precision Engineering for Consistent Results

Every flute and angle is cut just right so chips fly off clean and the surface comes out ready for sintering.

Compatibility With Major CAD/CAM Systems

Our burs run happy in pretty much anything with an open tool library. Small labs love that they don’t have to stock ten different brands.

Quality Control Standards at XANGTECH

We check every batch under a scope—sharpness, runout, straightness. Nothing leaves unless it’s dead on.

FAQ

Q: What is the average lifespan of a CAD CAM milling bur?

A: The lifespan varies by material: tungsten carbide burs can last 100–200 units depending on material milled; diamond-coated burs may last 50–100 units. Proper maintenance extends their life.

Q: Can I use one type of bur material for all dental materials?

A: While some versatile options exist, it’s recommended to match the bur material to the workpiece. For example, diamond-coated burs are better suited for hard ceramics, while ceramic burs are ideal for PMMA.

Q: How do I know when it’s time to replace my milling bur?

A: Signs include reduced cutting efficiency, increased vibration during milling, visible wear on the tool tip, or poor surface finish on restorations. Regular inspection is key.