Denture Milling Machines in 2025

What is a Denture Milling Machine and How Does It Work?

A denture milling machine forms an important part in the digital setup of current dental labs. It builds prosthetic items like complete or partial dentures with strong accuracy. These machines run on subtractive building methods. In other words, they shape the end prosthetic from a firm piece of material such as PMMA, zirconia, wax, or titanium. The steps follow computer-aided design and manufacturing (CAD/CAM) setups. This makes sure the finished product matches the starting digital plan with fine detail.

The method brings solid accuracy, reliability, and steadiness to dental prosthetics creation. Such detail lowers the call for hand changes. It cuts patient time in the chair a lot. Plus, it betters treatment results. Machines differ by axis numbers—often 4-axis or 5-axis. These decide the range of actions and forms they handle.

Why Are Denture Milling Machines Gaining Popularity in 2025?

A number of reasons drive the wider use of denture milling machines in 2025. For one, demand grows for same-day prosthetic fixes. This makes old multi-day building processes less attractive. Patients look for quicker finish times. Yet they want no drop in standards.

Also, steps forward in CAD/CAM tech have brought these machines within reach and at lower cost for dental labs in all scales. As hopes for detail, ease, and tailoring keep climbing, dental workers turn to milling machines for stronger outcomes.

Better cost and reach of CAD/CAM technologies, together with better automation skills, turn denture milling machines into must-have tools in today’s dental repair work.

Key Features to Consider When Choosing a Denture Milling Machine

What Specifications Matter Most for Performance and Precision?

When looking at a denture milling machine, a few tech details hold big weight in how it performs:

- Axis Configuration: A 5-axis machine gives wider motion range than a 4-axis type. Thus, it deals with tough shapes like full arch repairs or tilted implants.

- Spindle Speed and Torque: Quicker spindle speeds bring even surface ends and speedier making rounds.

- Material Compatibility: The machine needs to work with many materials. These include PMMA, wax, zirconia, titanium, and PEEK.

- Machining accuracy: 0.01mm serves as a usual measure. It keeps small shifts from digital plans. This proves key for fit and role.

How Important is Software Integration and Workflow Compatibility?

Software linking counts as much as hardware details. A well-linked system lets workers shift from scan to design to milling with little trouble. Open systems bring more choice. They back outside materials and software. Closed systems might hold users to brand-only parts.

Automation parts also lift output. Auto tool changers shorten wait times between work. Built-in calibration setups hold cutting detail as time passes. These parts help most in busy labs. There, speed matters above all.

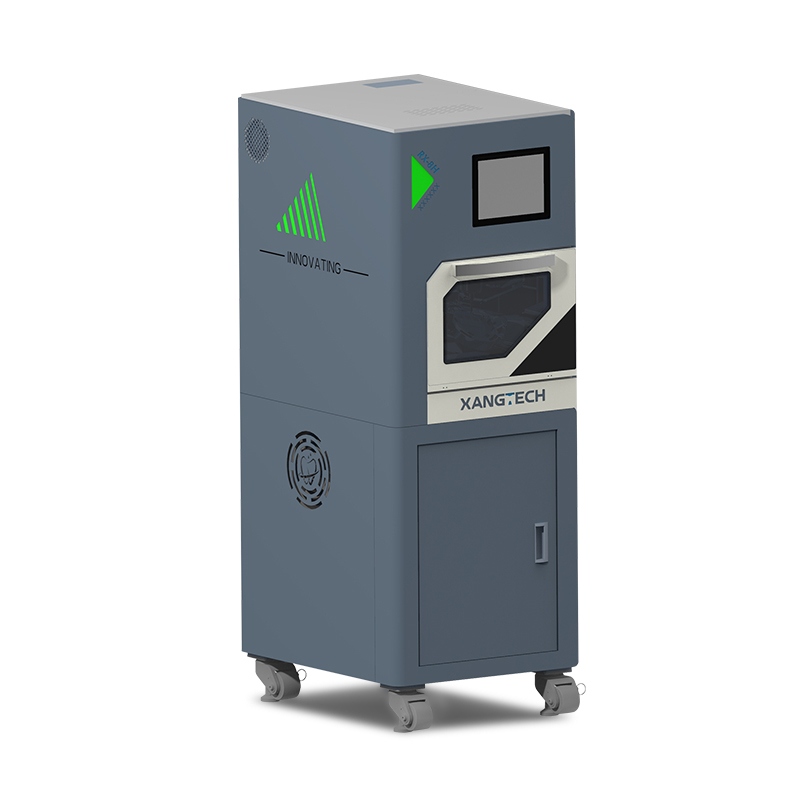

XANGTECH’s Dental Milling Machines: Innovation Meets Precision

Who is XANGTECH and Why Are Their Products Trusted by Professionals?

At XANGTECH, we offer more than ten years of skill in dental lab gear making. Our aim is to give full answers for dental workers everywhere. We supply fine products like zirconia blocks, PMMA discs, and top denture milling machines.

Our machines take shape with both work and ease in view. This lets dental labs hit best results with less work and time. With sales to over 20 countries worldwide, our products gain trust for steady work and new ideas.

What Makes the XT50 Milling Machine Suitable for Versatile Applications?

Key Capabilities of the XT50 Model:

Our XT50 milling machine takes form to handle the hard needs of today’s dental labs, maximizing both productivity and precision.

It has 5-axis simultaneous milling with a B-axis angular range of +350° to -910°. This lets it shape tough forms like large-angle implants. Best for front milling, the 90-degree vertical cutting feature facilitates detailed enamel-like texture finishes, producing high-quality prosthetic restorations. Its compact footprint allows integration into smaller labs without sacrificing performance.

The C-type clamp boosts material use by up to 20%. This cuts waste a great deal. Its power-off resume function ensures uninterrupted operation by automatically resuming milling tasks after unexpected stops, enhancing workflow continuity.

How Does the RX-8Y Milling Machine Optimize Workflow Efficiency?

RX-8Y Highlights:

The RX-8Y milling machine is our forward solution for both chairside and lab spots. The XANGTECH dental RX-8Y milling machine stands out as a cutting-edge solution in the dental industry, offering 5-axis linkage cutting technology that supports large-angle precision grinding.

It can process up to 8 different materials simultaneously, making it highly versatile. With an intuitive touchscreen interface, smart water level monitoring system, and automatic circulating water control, users benefit from seamless operation and consistent results.

The user experience is enhanced with a smart, upgraded large touch-screen interface, providing intuitive operation that streamlines the workflow. These features ensure that dental technicians can maintain speed without compromising quality.

Why Choose the RX-8H Metal Milling Machine for Metal-Based Prosthetics?

Features Tailored for Metal Processing:

For metal-based uses such as titanium or cobalt-chrome frameworks, our RX-8H model gives top performance. XANGTECH RX-8H metal milling machine is an intelligent device specially developed for high-precision dental processing scenarios, integrating advanced systems like dynamic suction, water cooling, and cutting oil circulation.

It comes pre-installed with Millbox software supporting one-click cutting and real-time monitoring. The operation interface is simple and intuitive, the process is visualized, and there is a caring guide at every step, making it ideal even for beginners.

Intelligent functions such as one-click calibration, automatic detection, needle compensation ensure accuracy while the robust construction provides vibration-free performance during heavy-duty tasks.

FAQ

Q: What materials can be used in denture milling machines?

A: Most denture milling machines support materials like PMMA (for temporary dentures), wax (for try-ins), zirconia (for aesthetic restorations), PEEK, and some models also support metals like titanium or cobalt-chrome.

Q: Are denture milling machines difficult to operate for beginners?

A: Modern machines are designed with user-friendly interfaces, automated calibration systems, and guided workflows that make them accessible even to users new to digital dentistry.

Q: How long does it take to mill a full denture using these milling machines?

A: Depending on the machine model and material used, milling a full denture can take anywhere from 30 minutes to 2 hours — significantly faster than traditional methods which may take days.