What Is a Dental Press Furnace and Why Does It Matter?

What Does a Dental Press Furnace Actually Do?

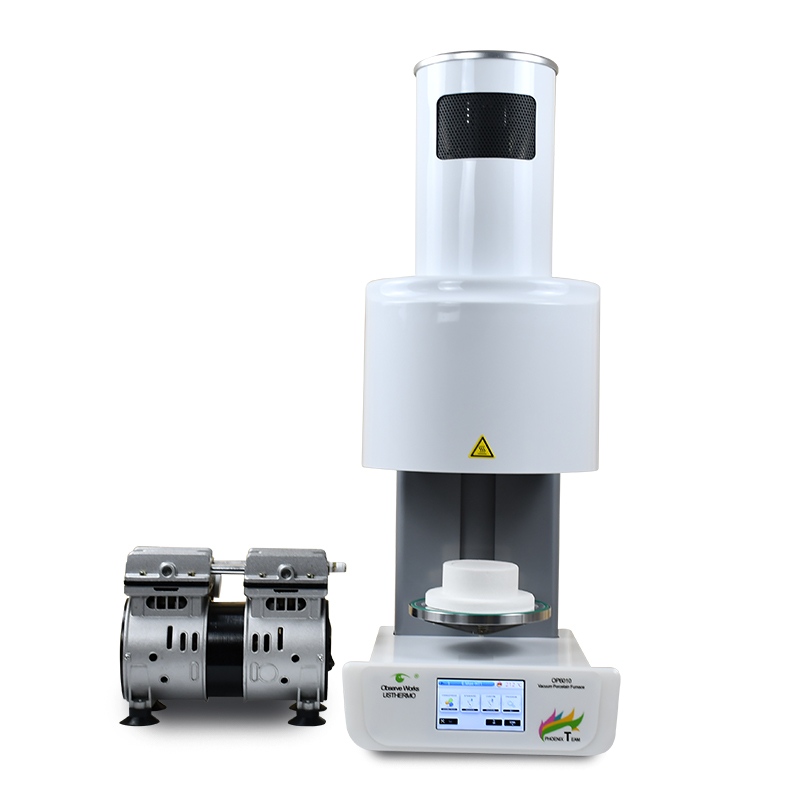

A dental press furnace is a specialized tool used to make highly accurate and tough ceramic dental restorations. Basically, this dental press is a unique furnace that applies heat and force to turn a ceramic ingot into a strong, attractive dental restoration. This method is key in producing crowns, veneers, inlays, and onlays with the pressable ceramics approach.

The main job of a dental press is to create dental restorations precisely. It does this by pushing melted ceramic material into a detailed mold. Thanks to exact temperature management and pressure oversight, the furnace makes sure the ceramic fills every detail of the mold. As a result, you get a restoration that matches natural teeth in structure and appearance.

Dental labs depend on press furnaces every day. They use them to produce restorations with great edge fit, clear translucency, and solid strength. This is especially true when working with lithium disilicate or glass ceramics.

Why Is Temperature Control So Critical in Dental Applications?

Temperature control is extremely important in dental work. Small mistakes can cause big problems for the end result. If the ceramic doesn’t get enough heat, it won’t flow right. This leads to an unfinished or warped restoration. Too much heat, however, can make it brittle or lead to cracks. These issues weaken the prosthetic’s strength.

Exact heating allows the ceramic to hit the perfect thickness for pressing. Steady temperature management boosts accuracy in shaping. It also helps ensure the restoration lasts a long time, like in crowns and bridges.

Spotting Common Issues in Your Dental Press Furnace

Why Won’t My Furnace Heat Up Properly?

If your dental press furnace isn’t warming as it should, begin with the power source. Is it firmly plugged in and steady? A loose connection or bad outlet might be to blame.

Then, examine the heating element. Check for obvious damage, wear, or cracks. If it looks fine but still fails to heat, a broken thermocouple could be the problem. This sensor handles temperature reading and control. A faulty one might stop the furnace from hitting or holding the right heat.

What If the Pressing Cycle Stops Midway?

A pressing cycle that halts in the middle can be annoying. Often, it’s caused by power cuts or software errors. See if your unit shows error codes on the control screen. These usually highlight the exact problem.

Mechanical problems can also cause this. The pressing piston might be stuck or out of place. Such issues could block the ceramic ingot from pressing into the mold correctly. This stops the whole process.

Is It Normal for My Press Furnace to Make Strange Noises?

A soft hum is typical during use. But odd sounds like clicking or buzzing need quick attention. Clicking might signal trouble with inner relays or loose components. A strong buzz or whine could mean a worn-out fan motor.

Always stop using it and check right away. Unusual noises often warn of bigger troubles ahead.

Troubleshooting Like a Pro: Easy Fixes You Can Try in Your Lab

Can I Reset My Dental Press Furnace on My Own?

Yes, most dental press furnaces have a reset button built in. Look in your user manual for its spot. If the furnace acts glitchy without an error code, try unplugging it for a short time. Then restart it. This can fix small software issues.

How Do I Maintain the Heating Element and Chamber?

Keeping your furnace clean is vital for good performance. Wipe away dust or ceramic bits from the chamber often. Use tools that aren’t metal. Never touch the heating element with hands or tools. It’s fragile and can get harmed by oils or marks.

A spotless chamber supports even heating. It also lowers the chance of dirt getting into the pressing process.

What Should I Do If Error Codes Keep Appearing?

Today’s furnaces show error codes to help with fixes. Here are some usual ones and their meanings:

Common Error Codes and Their Meanings:

- E01 – Overheating:Check if your cooling fan is running well and make sure there’s good airflow around the unit.

- E03 – Temperature sensor failure:This often means a problem with the thermocouple; look at its connections.

- E07 – Press piston error:Adjust the pressing system or check for clogs that might block its motion.

Don’t brush off ongoing error codes. They give the first hints of serious problems that could affect your restoration quality.

Understanding Preventive Maintenance for Longer Lifespan

How Often Should I Service My Press Furnace?

If you use your dental press furnace a lot, do simple cleaning each week. Get a full check from a skilled technician every 6 to 12 months. This catches problems early.

Steady upkeep stops unexpected failures. It also makes key parts last longer.

What Parts Wear Out Over Time?

Like other high-end gear, certain parts slowly break down:

Components That May Need Replacing:

- Heating elements slowly lose their power after heavy use.

- Thermocouples can get less precise as time goes on.

- Seals and insulation materials wear down from constant high heat.

Watching these parts closely keeps your furnace dependable and steady.

Meet XANGTECH: Reliable Performance in Every Press Cycle

Why Choose XANGTECH’s Dental Press Furnaces?

At XANGTECH, we’ve built our dental press furnace for both efficiency and ease. Our units work without needing compressed air. This makes setup simpler and cuts down on maintenance work. This smart furnace shines because it runs without compressed air. It eases both setup and care.

The furnace is made for easy upkeep. That means lower costs for maintenance and less time out of service. You’ll like its sturdy build that gives sharp edge accuracy. This is crucial for fine restorations like veneers and tricky bridges.

Whether pressing lithium disilicate ingots or other ceramics, our unit manages it smoothly. It does this with its two-way role: pressing and porcelain tasks.

What Sets XANGTECH Furnaces Apart from Others?

Key Features You’ll Appreciate:

- Smart digital controls with easy programming.

- Quiet running that keeps your lab calm.

- A small but strong design that fits any space well.

- Sharp edge accuracy and low chance of failure for steady daily work.

With our XANGTECH press furnace, you’re not just getting gear. You’re gaining reliable quality and simple handling.

FAQ

Q: How long does it take to complete one pressing cycle in a dental press furnace?

A: It usually takes about 15–25 minutes depending on material type and settings used, including heat-up, hold, and pressing stages.

Q: Can I use different types of ceramics in one press furnace model?

A: Yes, most modern dental press furnaces like those from XANGTECH support multiple ceramic materials—just make sure to follow manufacturer guidelines for each type.

Q: What should I do if my press furnace isn’t reaching its target temperature?

A: Check that the power source is stable, inspect the heating coil, and verify that no error codes are active; if issues persist, contact technical support for help.