How a Dental Press Furnace Works and Why It’s a Big Deal

What’s a Dental Press Furnace and How Does It Do Its Thing?

A dental press furnace is a special tool used in dental labs to whip up top-notch ceramic restorations like crowns, bridges and veneers. It heats ceramic materials to super high temps until they’re soft enough to shape. Then, it presses them into molds using mechanical or air pressure to match the exact design needed for the restoration.

Why Is a Dental Press Furnace a Must in Today’s Dentistry?

Two Jobs in One: Pressing and Ceramic Firing

Dental press furnaces are key because they can handle two tasks at once. They press ceramic materials and fire porcelain in a single machine.

This all-in-one setup saves space and makes the work smoother by cutting down on extra gear.

Uses for Crowns, Bridges and Veneers

Dental press furnaces are used to make all kinds of restorations:

Crowns: Single-tooth fixes that need to be tough and look good.

Bridges: Multi-unit setups to replace missing teeth.

Veneers: Thin layers stuck to the front of teeth to boost their look.

These jobs need precision and reliability, which modern press furnaces deliver with controlled heat and accurate pressing.

What Materials Work with Dental Press Furnaces?

Lithium Disilicate and Other Common Ceramics

Dislicato de litio is a top pick for dental press furnaces because of its great strength and good looks.

From an aesthetic perspective, lithium disilicate excels in delivering restorations with superior translucency and color matching. XANGTECH lithium disilicate offers significant advantages for dental restorations, characterized by its high chemical stability and impressive bending strength, which contribute to the longevity and reliability of the final prosthesis.

Other ceramics like leucite-reinforced glass ceramics also work when tweaked for specific firing cycles.

Key Features to Look for in a Dental Press Furnace

What to Think About Before Buying a Press Furnace?

Picking the right dental press furnace means checking out a few techy features that affect how well it works and how easy it is to use.

Temp Accuracy and Control Systems

Getting the heat just right is super important for steady results. A solid furnace should have:

High max temps (usually up to 1200°C)

Steady heating rates

Accurate temp sensors

These specs make sure you get the best pressing or sintering without wrecking delicate materials.

Customizable Settings

Modern furnaces should let you set up programs tailored to specific materials or restoration types. This flexibility makes them work well with different lab setups.

Safety Features and Easy Controls

A simple control panel cuts down on training time and keeps things safe. Look for stuff like:

Touchscreen controls

Built-in safety limits

Overheat protection

Vacuum calibration systems

How Does Tech Make Dental Furnaces Better?

Automation and Smoother Workflows

Automation is a game-changer for getting more done. Advanced models have auto-start cycles, error alerts and real-time checks that cut down on mistakes.

Works with Digital Dentistry Tools

Hooking up with CAD/CAM systems boosts precision by linking digital designs straight to physical restorations. This cuts down on time while keeping things super accurate.

Meet XANGTECH’s Dental Press Furnace Solutions

Why Pick XANGTECH for Your Dental Lab?

We bring over 11 years of know-how in top-quality dental lab gear. Our mission is clear:

With 11 years of experience, Nanyang Liandong Biotechnology Co., Ltd. specializes in dental laboratory materials and equipment. Our mission is to deliver one-stop solutions and exceptional service to dental professionals worldwide.

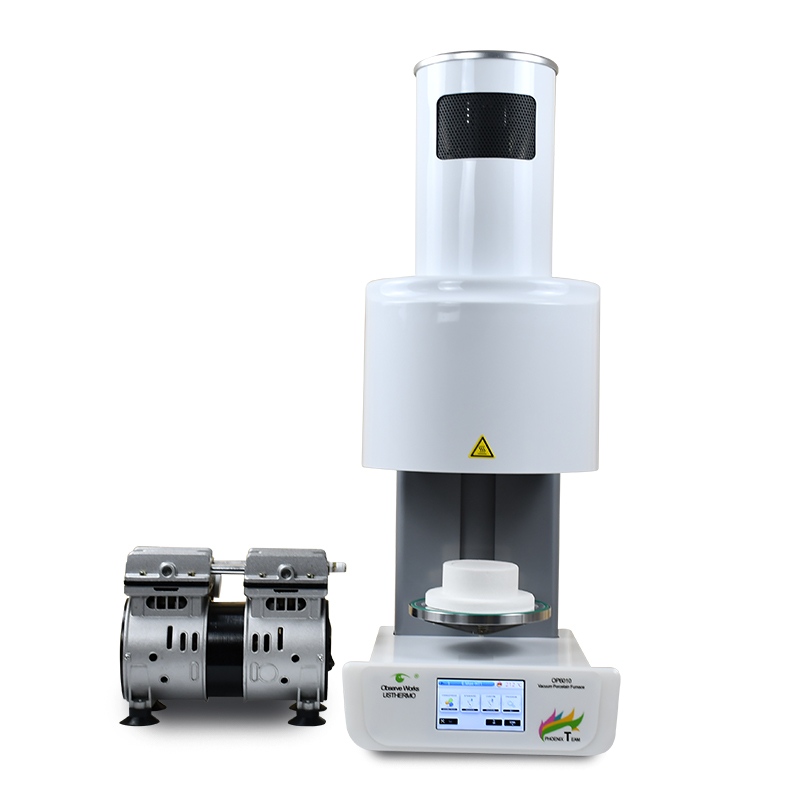

XANGTECH press furnace, designed to elevate performance and reliability in dental laboratories and clinics. This advanced furnace stands out for its ability to operate without the need for compressed air, simplifying both setup and maintenance.

Versatility is at the heart of our press furnace, as it is equipped to handle both pressing and porcelain functions. This dual capability makes it an invaluable asset in any dental practice, capable of accommodating a variety of procedures and materials.

Our press furnace stands out because:

- No need for compressed air

- Low maintenance cost

- High edge precision

- Dual-functionality: pressing & porcelain

The furnace’s innovative design provides comprehensive functionality while maintaining efficiency, offering a seamless integration into any workflow.

These perks make our product perfect for both small clinics and big labs looking for reliability without the hassle.

How Does XANGTECH Press Furnace Make Work Easier?

Our design focuses on being easy to use without skimping on quality:

By eliminating the need for compressed air, our press furnace not only reduces operational complexity but also ensures consistently excellent results across a range of applications. Its robust construction guarantees high edge precision while also maintaining a low probability of failure to ensure dependable performance over time.

Plus, we provide network technical support during the warranty period.

Preguntas frecuentes

Q: What’s the difference between a press furnace and a ceramic furnace?

A: A press furnace does both pressing (shaping ingots into restorations) and ceramic firing (sintering or glazing). Ceramic furnaces usually just handle firing.

Q: How long does a pressing cycle take in a dental press furnace?

A: It depends on the material, but it usually takes 30–60 minutes for a cycle, including heating up, holding at peak temp, pressing and cooling down.

Q: Can beginners run a dental press furnace easily?

A: Yup. Most modern ones like ours have easy-to-use controls with pre-set cycles that make it simple even for newbies. Safety features also help keep things smooth and safe.