What Makes Lithium Disilicate a Top Pick in Today’s Dentistry?

Lithium disilicate has turned into a key player in modern dentistry. It offers a great mix of features that handle both function and looks.

Why Do Dental Technicians Love Lithium Disilicate?

Dental techs pick lithium disilicate for its solid mix of strength and beauty. This stuff lets them make restorations that handle mouth forces. It also matches the see-through look and color of real teeth. That’s perfect for front and back teeth work.

Key Features That Boost Restoration Quality

Strength and Looks

Lithium disilicate stands out for its high bend strength, from 360 to 400 MPa. This keeps it tough against chewing. It also keeps a natural enamel look. You can etch and bond it too. That boosts how long restorations last and stay steady.

Flexibility in Uses

Lithium disilicate’s flexibility is another big plus. It works for many dental fixes like veneers, crowns, bridges, inlays, and onlays. This makes it a go-to for dentists facing different cases.

Works Well with Pressing Methods

Lithium disilicate fits great with pressing methods. You can press it into exact shapes using a dental press furnace. That gives high detail and accuracy in the final piece.

How Does the Pressing Process Affect the Final Restoration?

The pressing process really shapes the quality of lithium disilicate restorations.

What Does a Dental Press Furnace Do in the Workflow?

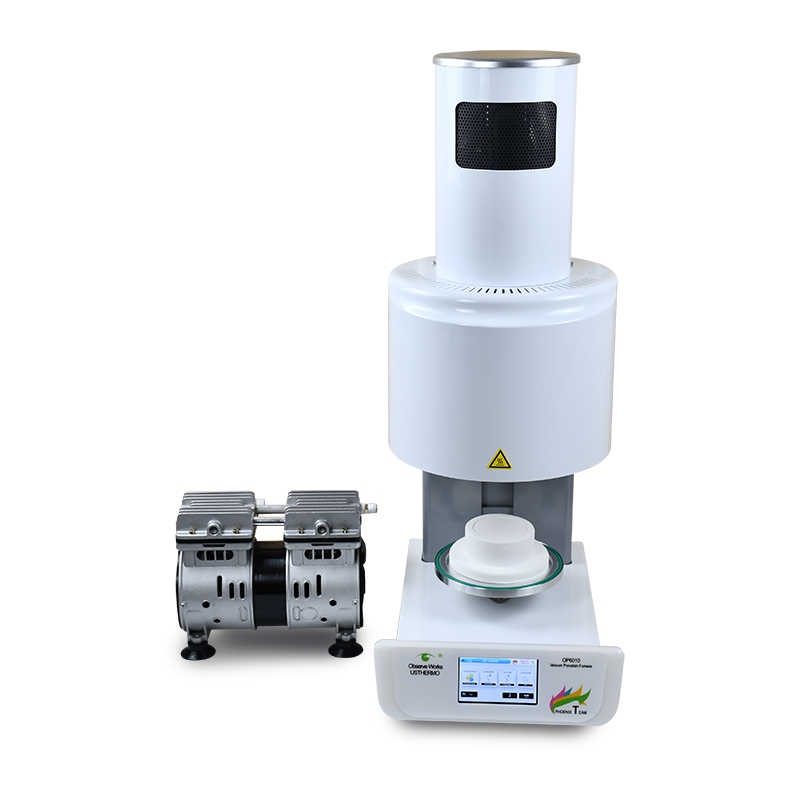

A dental press furnace is a must for top results with lithium disilicate.

Temperature Control and Cycle Accuracy

Spot-on temperature control matters during pressing. It gets the material to the right thickness without hurting strength or looks. The furnace’s cycle accuracy gives steady results across many presses.

Why Vacuum and Pressure Settings Matter

Right vacuum and pressure settings remove air bubbles. They create dense restorations without flaws. This step is key for finishes that look like real teeth.

Common Pressing Mistakes and How to Dodge Them

Overheating or Underheating the Ingots

Too much heat can discolor or weaken the material. Too little heat leads to partial pressing. Stick to manufacturer temperature guides to skip these problems.

Partial Presses or Cracks While Cooling

Partial presses happen from low pressure during the process. Cracks while cooling come from quick temperature shifts. Slow cooling steps help avoid heat shock.

Pro Tips to Get Better Pressing Results

How Can You Improve Edge Fit and Surface Feel?

Good Wax Patterns Before Pressing

Exact wax patterns are key for tight edge fits. Clean wax without flaws leads to better-fitting restorations after pressing.

Invest Materials and Size Control

Top invest materials keep size steady during pressing. Managing expansion is vital for fit, especially on detailed designs.

What Are the Best Ways to Pick Ingots and Preheat Them?

Matching Ingot Color to Final Goals

Pick an ingot color that fits the end restoration shade. This blends seamlessly with nearby teeth.

Preheat Timing from Manufacturer Guides

Follow the exact preheat time from instructions. This gets ingots ready for pressing. It cuts risks of flaws or weak spots.

Introducing XANGTECH: Accuracy Meets Power in Dental Press Furnaces

We at XANGTECH get how vital accuracy is in dental restorations. Our dental press furnaces give top-notch accuracy and repeat results in every press cycle.

Why Pick XANGTECH for Your Lithium Disilicate Pressing?

Design Focused on Accuracy and Repeat Results

Our design delivers steady outcomes. It uses advanced tech to cut errors during pressing.

Easy Interface for Better Workflow

Our simple interface makes operation smooth. Users can streamline their work without losing quality or accuracy.

Features That Make XANGTECH Dental Press Furnaces Stand Out

Multi-Step Heating Plans

XANGTECH furnaces have multi-step heating plans made just for lithium disilicate. They ensure even heat spread in each cycle.

Live Monitoring and Check Tools

Live monitoring gives instant feedback on settings. Check tools spot issues before they hurt results.

Small Design for Lab Efficiency

Built for lab efficiency, our small units save space. They keep the performance modern dental labs need. XANGTECH press furnace offers comprehensive functionality while maintaining efficiency, offering a seamless integration into any workflow.

Preguntas frecuentes

Q: What is a dental press furnace used for?

A: A dental press furnace is used primarily for processing materials like lithium disilicate into various dental restorations such as crowns or bridges by applying heat under controlled conditions. XANGTECH press furnace stands out for its ability to operate without the need for compressed air, simplifying both setup and maintenance.

Q: How do I choose the right press furnace for lithium disilicate restorations?

A: Consider factors like temperature control precision, vacuum settings, ease-of-use features such as intuitive interfaces, and real-time monitoring capabilities. XANGTECH offers solutions tailored specifically toward optimizing workflows involving this versatile ceramic material.

Q: Can pressing parameters affect the strength of lithium disilicate restorations?

A: Yes! Improperly set parameters such as incorrect temperatures or inadequate pressure levels can compromise structural integrity leading potentially weaker results than expected. XANGTECH’s engineering focuses on accuracy ensuring consistent outcomes through carefully calibrated cycles every time you use our equipment.