Angle de travail de l'axe de rotation: A: 360 ° B: 35 °-91 °

Vitesse de broche: 0-60,000rmp

Puissance: 1.5KW

Pression nominale de travail: 6.0-7.5bar (anhydre, sans huile)

Précision d'usinage: 0,01 mm

Size:550*660*760

Layout CAD Software: Open System

Processing Time:Full crown<15min,3 bridges<30min

tension: 220-230V

tool magazine: 10

Épaisseur du matériau usinable: 10-30mm

Weight:155kg

Processing Method: 5 axis linkage,dry milling

Needle Specifications: Knife handle diameter 4mm automatic tool change

Machinable Material:Zirconia,Wax tray/PMMA PEEK,Composite Materials

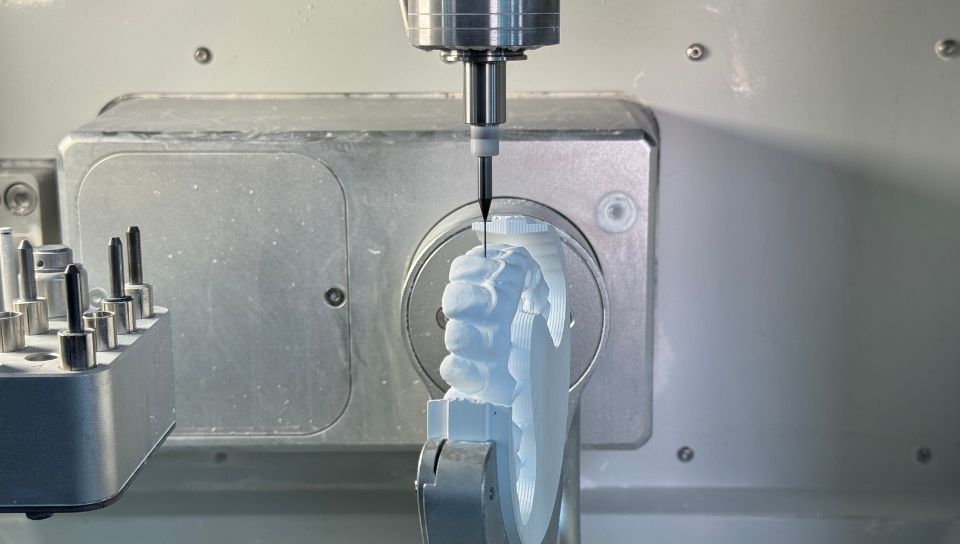

Processing Type: Veneer,Single Crown,Inlay,Bridge Body,Abutment,Sleeve Crown

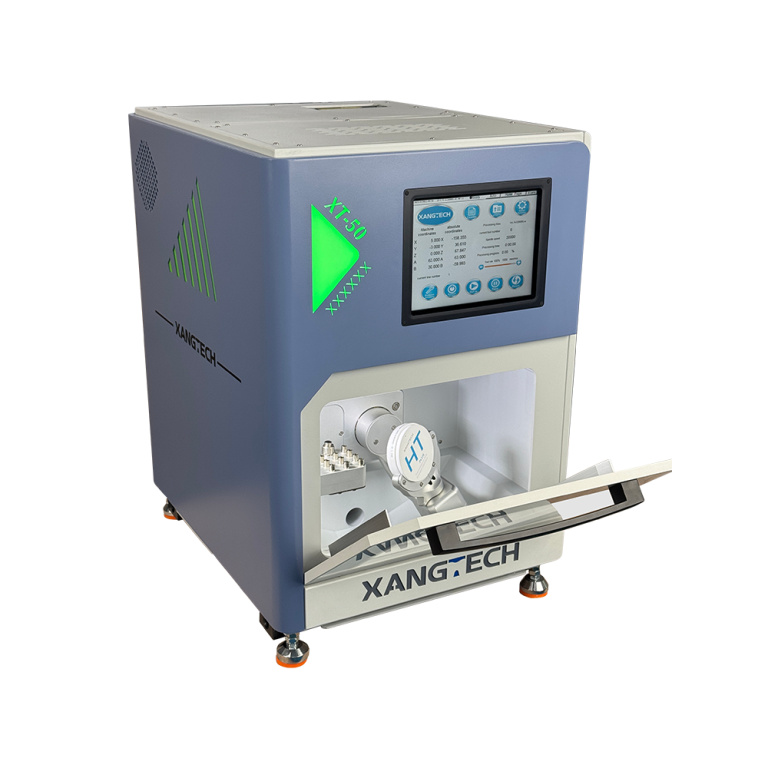

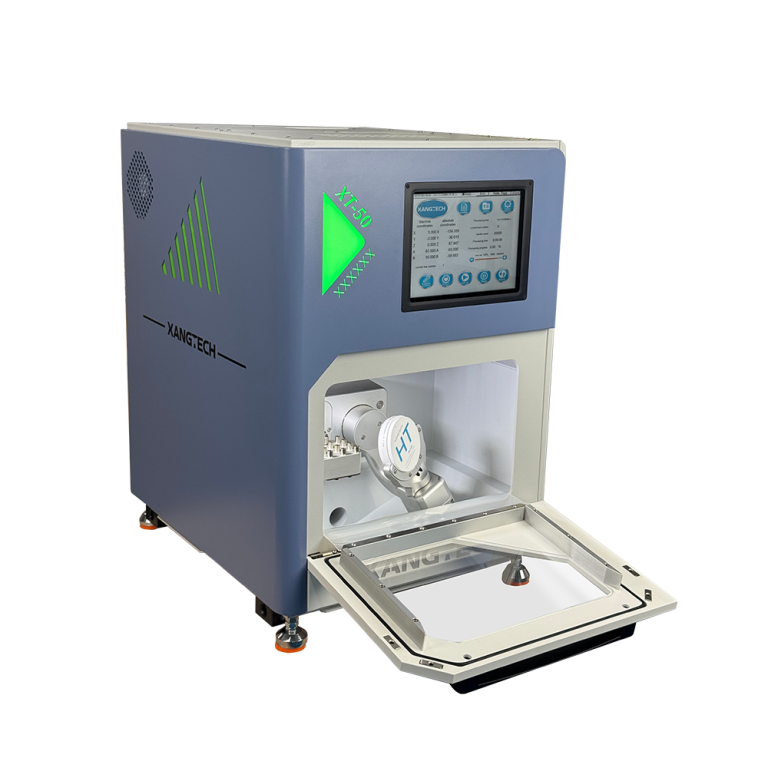

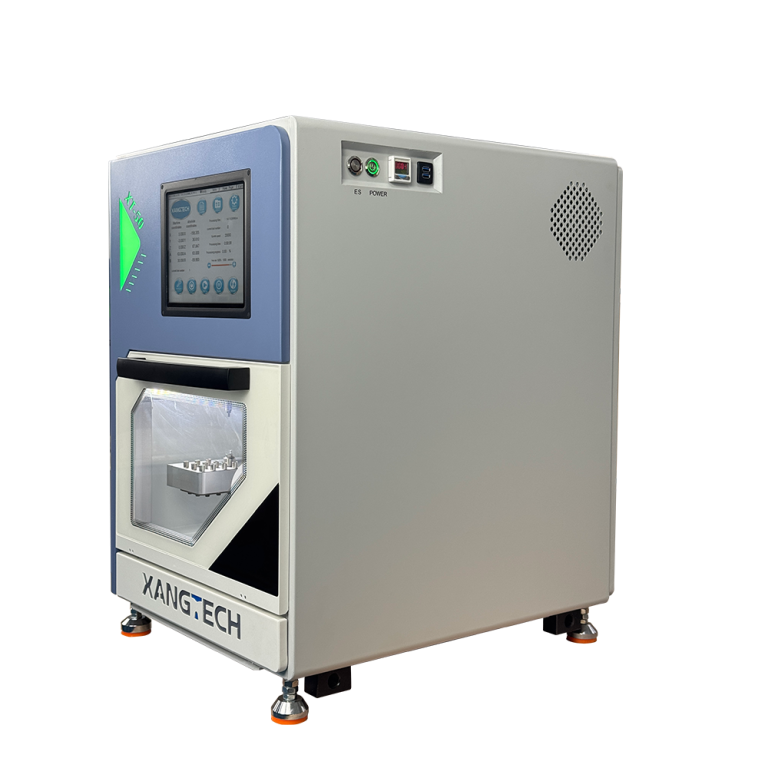

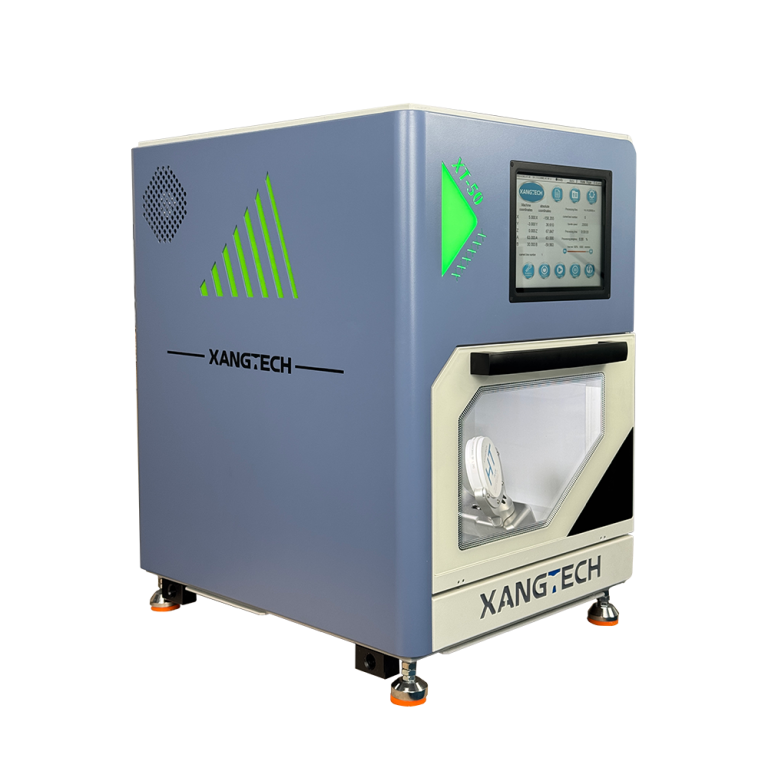

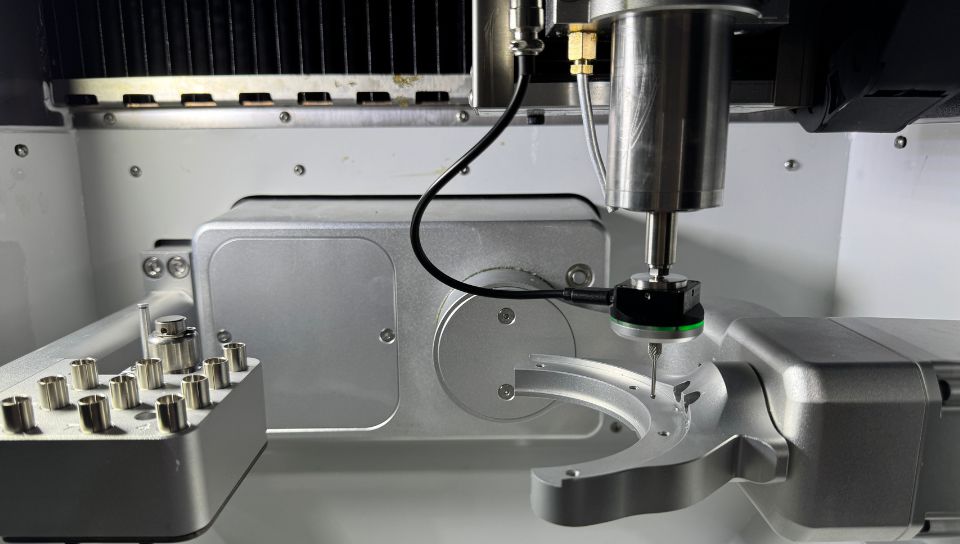

XANGTECH XT-50 dry milling machine has numerous intelligent features, providing you with the best dental solution. Our XT-50 zirconia milling machine is equipped with a power-off recovery function. In the event of a dental emergency or interruption during machining, it can automatically resume processing, effectively avoiding repetitive work that increases processing time and reduces efficiency.XANGTECH XT-50 dental zirconia milling machine’s built-in high-precision probe allows for one-click automatic calibration of the ABXYZ axis, and automatically detects milling bur’s life and wear, saving time and simplifying operation. Simply plug in and start working. Furthermore, it can cut dental materials vertically at 90 degrees. This allows for more precise tooth pattern processing when milling incisors, helping to provide customers with more realistic dentures. Furthermore, its wide B-axis angles, reaching +35° and -91°, perfectly accommodate large-angle implants. To conserve dental materials and avoid unnecessary waste, our XT-50 zirconia 5 axis dental milling machine utilizes a C-type clamp, significantly improving material utilization by 20%. XT-50 zirconia dental lab milling machine is not only highly efficient and stable, but also has industry-leading processing speeds, including automatic tool change in a 10-tool magazine and single-crown machining in no more than 13 minutes . XANGTECH XT-50 dry zirconia milling machine adopts an integrated dust-proof silicone structure that can fit tightly into the gaps of the equipment. It not only effectively prevents the dust generated during the cutting of dental materials, such as bloc de zirconie, from invading the interior of the milling machine, but also reduces the wear of core components, extends their service life, and reduces subsequent maintenance costs.Its many intelligent features, coupled with our reliable 24/7 online after-sales service, which provides immediate feedback within 1 hour of any question, solve all dental problems for you.

1.Automatically resumes processing after interruption.

2.90-degree vertical cutting for anterior tooth textures.

3.Large-angle B-axisof +35° and -91°for large-angle implants.

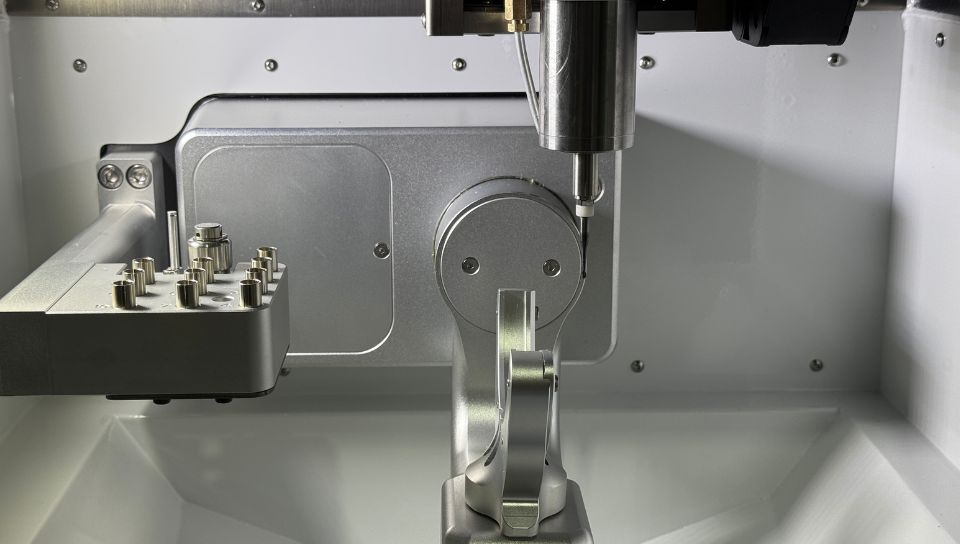

4.C-type fixture improves material utilization by 20%.

5.Automatic toolwear detection and calibration of the axis.

6.10-tool automatic change, single crown processing ≤13 minutes.

7.Integrated dust-proof silicone structure prevents dust from invading the interior of the body.

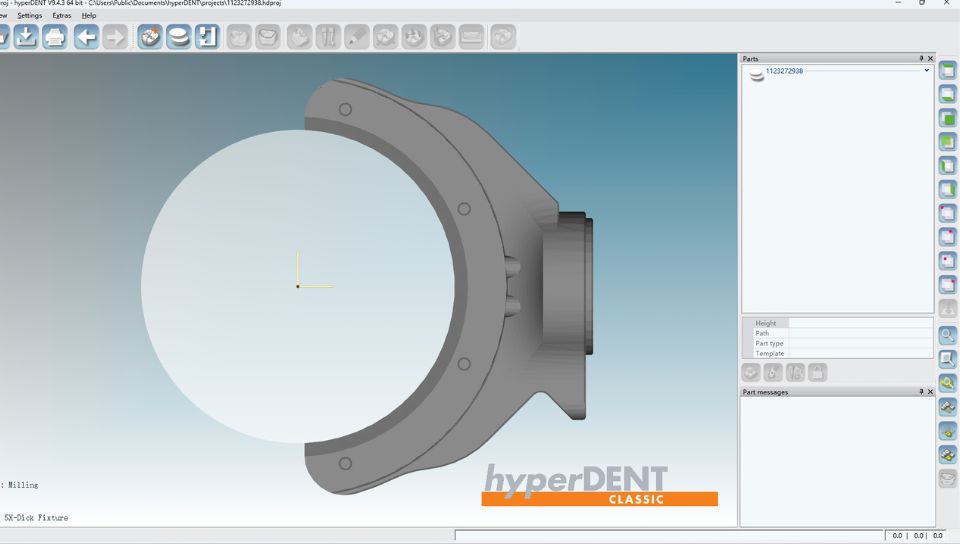

8.The machine with optimized version of Hyperdent.

Working Demonstration