The Fundamentals of Dental Milling Machines

What Is a Dental Milling Machine and How Does It Work?

Dental milling machines have played a major role in the shift to digital dental care. They are sophisticated, computer-guided tools used to create dental restorations like crowns, bridges, dentures and implants. These devices rely on CAD/CAM technology. This tech turns a digital blueprint into an exact physical piece.

The process starts with scanning the patient’s mouth. Technicians use intraoral or lab scanners for this. The data then goes into CAD software. From there, the 3D design becomes tool paths. The milling machine follows these paths. It cuts the shape of a new tooth or group of teeth from a disc-shaped material with a milling bur.

Milling machines move along several axes (X, Y, Z and often rotational axes A and B). This setup allows for very precise cuts. It works well for detailed shapes in materials such as zirconia or lithium disilicate.

Key Components and Their Functions

- Spindle: This fast-spinning part grips the cutting tool. It handles the actual removal of material.

- Tool Changer: It swaps milling burs automatically during jobs. This matches the needs of various tool paths.

- Worktable: This is the surface where the material block sits firmly during milling.

- Control Software: It turns design files into exact tool paths. It also directs axis movements to guarantee accurate production.

The Importance of Rotation Axis Control in Dental Milling

Why Is Rotation Axis Control Critical for Precision?

Exact control of rotation axes is essential for top-quality restorations. Multi-axis setups let machines reach tricky angles and undercuts. Linear motion alone cannot handle these. A four- or five-axis machine can make more detailed pieces than one with fewer axes. Extra axes provide greater flexibility. This helps with undercuts and fine details.

Precise rotation leads to smooth surface finishes and correct dimensions. It matters a lot for complex forms or hard materials like zirconia. Better axis coordination also cuts down on waste. It does this by lowering mistakes and the need for re-milling.

Types of Axis Configurations in Milling Machines

3-Axis Systems

These setups move just in X, Y and Z directions. They work fine for simple jobs like basic crowns or inlays. However, they cannot mill shapes that need angled access.

4-Axis Systems

These add the A-axis, which rotates around the X-axis. As a result, they manage tougher structures. They offer improved access to undercuts compared to 3-axis types.

5-Axis Systems

These include two rotational axes, often A and B or A and C. This gives full freedom in space. Top machines usually have five axes. They produce items faster. The results show better precision, strength and finish quality. This configuration suits full-contour crowns, bridges and implant abutments with fine details.

Strategies for Optimizing Rotation Axis Control in Practice

How Can Technicians Improve Axis Calibration?

Regular calibration keeps axes aligned properly. Technicians should use special calibration blocks or software tools to check accuracy. Keep firmware current for smooth work with CAD/CAM files. Run diagnostic programs to spot mechanical issues like backlash or shifts early on.

Techniques to Enhance Milling Accuracy Through Axis Optimization

Tool Path Optimization

Technicians can tweak tool paths in CAM software. This cuts down on extra rotations. It speeds up the work. It also lessens tool wear and boosts precision.

Material Positioning Strategies

Smart placement of the material block on the worktable reduces heavy axis turns. Positioning it near the machine’s rotation center improves stability while cutting.

Maintenance Best Practices for Axis Control Units

Lubricate spindles and guide rails often to avoid wear from friction. Check belts and motors regularly for signs of tiredness or slipping. Proper maintenance of your dental milling machine calls for these steps: regularly lubricating all moving parts, including the spindle and guide rail.

Common Challenges with Rotation Axes in Dental Milling Machines

What Are the Typical Issues Users Face with Rotation Axes?

Users often deal with misalignment from wear or poor calibration. Mismatches between software and hardware can cause uneven motions or failed milling runs. Dense materials like zirconia bring vibrations from quick rotary actions. These can lead to errors.

Troubleshooting Tips for Axis Performance Problems

Error Diagnosis Techniques

Watch the control software logs for odd movements or calibration faults. Most systems have built-in diagnostics. They alert you to problems as they happen.

Adjustment Procedures After Mechanical Shifts

After moving the machine or doing big repairs, reset all axes to zero. This sets correct starting points. It stops errors from building up in later jobs.

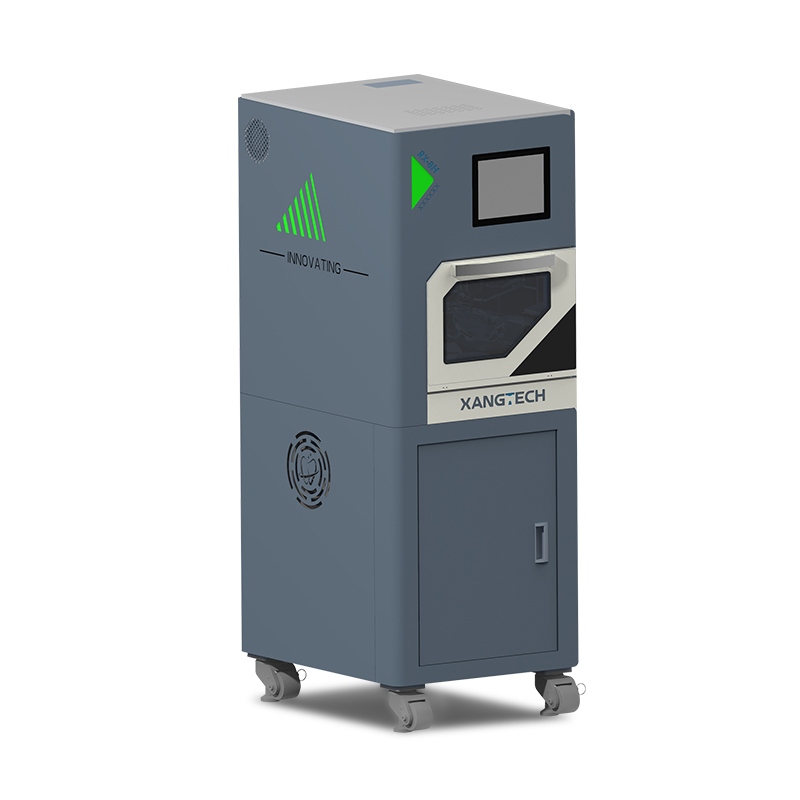

Introducing XANGTECH’s Dental Milling Machine Solutions

With 11 years of know-how, Nanyang Liandong Biotechnology Co., Ltd. focuses on dental lab supplies and tools. This includes carefully built 歯 tuned for rotation axis control.

What Makes XANGTECH’s Dental Milling Machines Stand Out?

Our XT50, RX-8Y and RX-8H models use smart multi-axis linkage systems. They tackle complex shapes with outstanding accuracy.

XANGTECH は XT 50 milling machine fits the tough needs of modern dental labs. It boosts both output and exactness.

Every machine has live feedback systems and smart correction algorithms. These adjust on the fly during use. They ensure steady outcomes with zirconia, PMMA, lithium disilicate and other dental materials.

Features Designed for Enhanced Rotation Axis Control

Intelligent Motion Algorithms

Our machines employ instant feedback loops. They fix small drifts right away while cutting. This keeps each restoration true to its digital plan with little difference.

High-Torque Rotary Motors

The RX-8H model has a 2.5KW motor. It holds steady rotation even under tough loads, like milling solid ジルコニア ブロック. It includes water cooling, dynamic suction, cutting oil circulation and multi-axis linkage control systems. These meet the full needs for fast processing of detailed dentures and restorations.

ユーザーフレンドリーなインターフェース

All our units come with easy-to-use touch-screen setups. They make axis calibration simple with step-by-step guides. This works well for techs new to advanced CNC tasks. The user-friendly interface is straightforward to handle. Even newcomers can start quickly.

FAQについて

Q: What is the difference between 4-axis and 5-axis dental milling machines?

A: 4-axis machines add one rotational motion, typically around the X-axis. This allows more angles than a basic 3-axis system. But they remain limited in certain ways. A 5-axis machine has two rotational axes. It provides total motion freedom. This is key for detailed work like full-contour crowns or implant frameworks.

Q: How often should I calibrate the rotation axes on my dental milling machine?

A: How often depends on how much you use it. But experts suggest every two weeks for normal runs. Do it after any upkeep that might shift alignment.

Q: Can improper axis control affect restoration fitment?

A: Yes, poor axis control can cause size errors. These might make a crown or bridge unfit in the patient’s mouth. It could lead to discomfort or the need to remake the piece.

Q: What should I do if I experience vibration issues during milling?

A: Check the spindle bearings. Tighten all fasteners on moving parts. You might also lower feed rates for hard materials like zirconia. This helps cut vibration errors.

Q: Are XANGTECH milling machines suitable for multiple materials?

A: Yes. Our RX-8Y model processes up to 8 materials at once. It gives great flexibility for uses from single crowns to elaborate implant setups. It combines key features like dynamic suction, a water cooling system, cutting oil circulation and air compression.