What is the Role of a Porcelain Furnace in Dental Restorations?

What Is a Porcelain Furnace and Why Is It Essential in Dentistry?

Porcelain furnaces serve a vital function in making top-notch dental restorations. These pieces are sturdy, durable and visually appealing. A porcelain furnace is a dedicated tool that heats dental ceramics—like porcelain, lithium disilicate and zirconia—to exact high temperatures. This happens while crafting dental restorations. It fires dental crowns, veneers and bridges from porcelain or ceramic materials.

The heating process, which includes phases for solidifying the material and for final glazing, changes powdered ceramic materials into compact, tough forms. These closely resemble the look and role of real teeth. The furnace raises the material to a high heat level. This causes it to melt together and create a solid, reliable item. Such restorative parts are key in dental work. They fix cavities, replace lost teeth and boost smile looks.

A good porcelain furnace delivers managed heating phases. These often cover pre-drying, high-temperature firing and last glazing steps. Such control is crucial for gaining strength and see-through quality. Porcelain furnaces vary in types and setups. They are vital for producing attractive and enduring dental restorations.

How Does Precision Firing Affect the Appearance of Dental Restorations?

Precision firing goes beyond a simple technical need. It shapes the look and work of dental prosthetics in key ways. Steady temperature control makes sure ceramic bits join evenly. This leads to steady color, clearness and power. Porcelain furnaces offer a reliable and even heating method. That is crucial for getting an exact and true fit of the restoration.

Spot-on heat management—usually within ±1°C—is key to copying natural tooth colors with stacked ceramics. Porcelain furnaces make certain the end result lacks flaws like cracks, holes and air pockets. These issues can harm the quality and life of the restoration. Even heating cuts down chances of flaws such as tiny cracks or stuck air bubbles. These affect both beauty and lasting power.

On top of that, a slow cooling step is important. Quick cooling can add inner strain in the ceramic build, causing bending or breakdown. The cooling process can last a few hours. It depends on the porcelain type and restoration details. This careful heat handling makes sure restorations appear natural and work well.

Key Features That Define an Effective Porcelain Furnace

What Temperature Ranges Are Required for Firing Dental Ceramics?

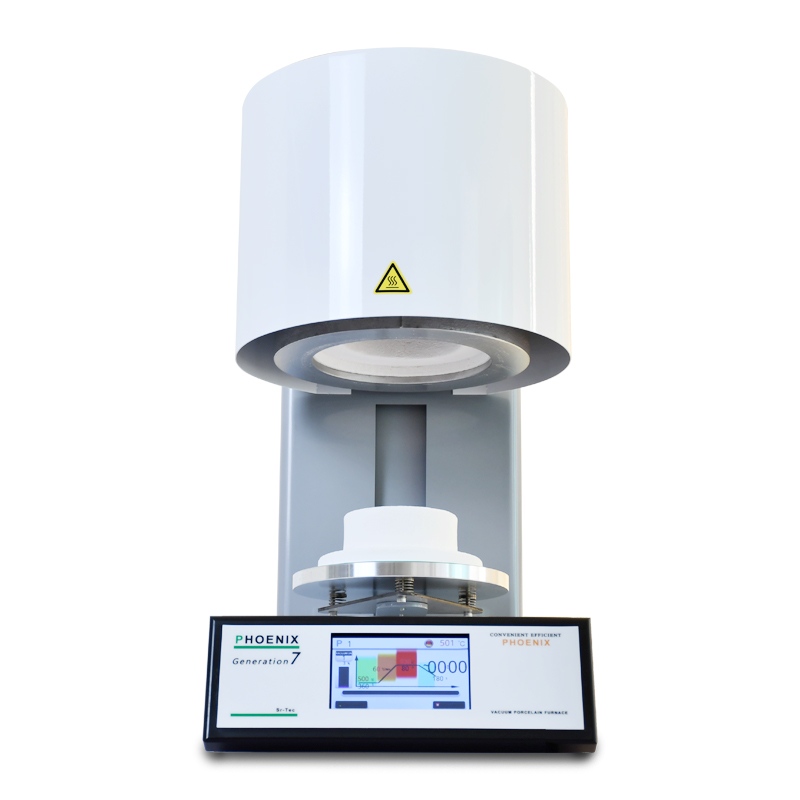

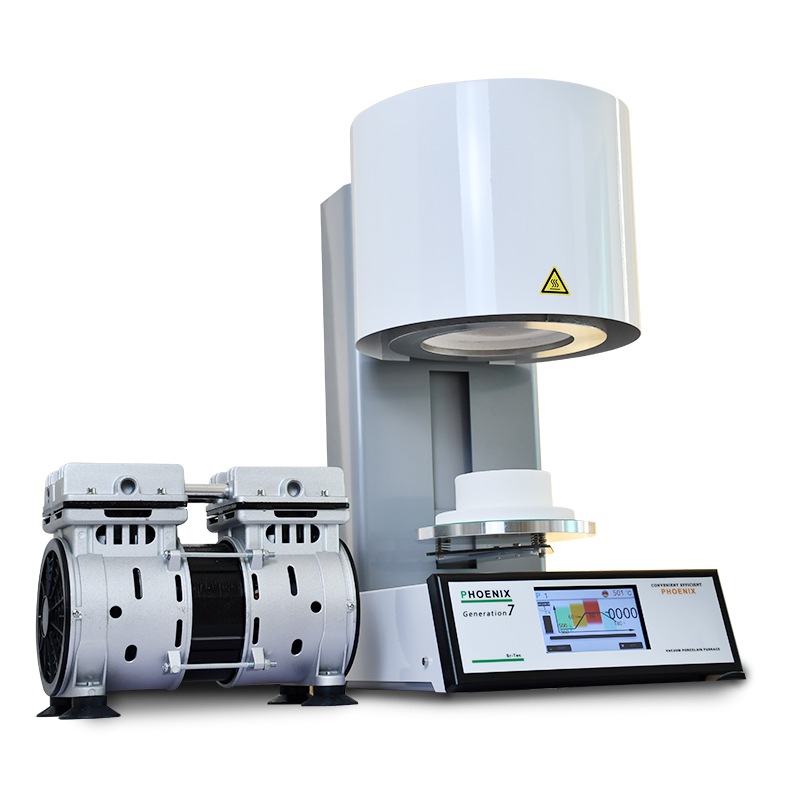

Various dental ceramics need set firing temperatures. The most common ones heat between 400°C and 1000°C. XANGTECH advanced porcelain furnace meets these demands with a top temperature of 1200°C. This makes it fit for different material kinds, including lithium disilicate and zirconia.

Multi-step firing plans are essential. Pre-drying gets rid of moisture. Firing toughens the ceramic. Glazing adds the last shine for looks. Top-notch automatic temperature tweaks, with exactness within ±1°C, ensure steady results over cycles.

Why Is Vacuum Firing Important in Dental Ceramic Processing?

Vacuum firing is key to removing air gaps in the firing step. These gaps can cause holes or weak join spots in the ceramic build. Our porcelain furnace offers a steady vacuum setting with power up to -97Kpa. It is perfect for fine ceramic work.

Clearing trapped gases boosts see-through quality. That is a major point for realistic restorations. It also raises mechanical power by ensuring tight joins. Even air control via vacuum lowers oxidation dangers in high-heat firings.

Introducing XANGTECH’s Porcelain Furnace Technology

What Sets XANGTECH’s Porcelain Furnaces Apart from Others?

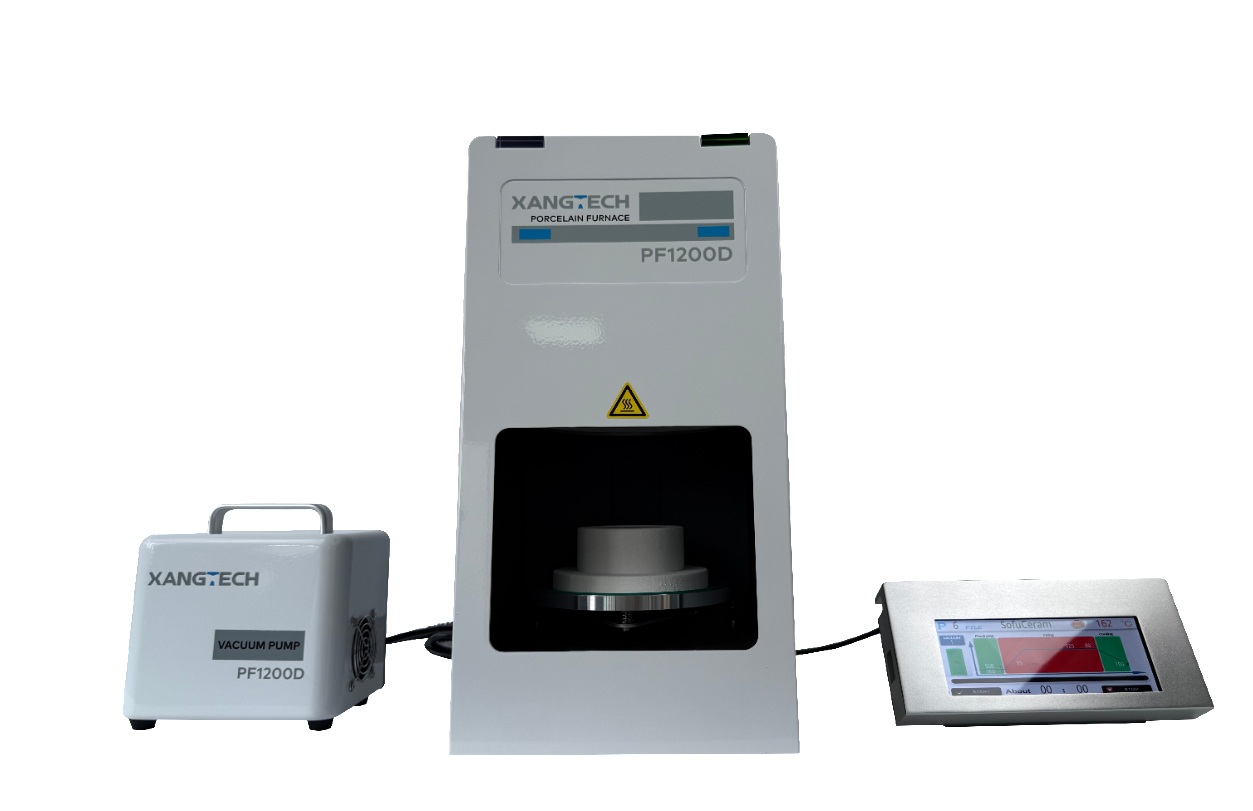

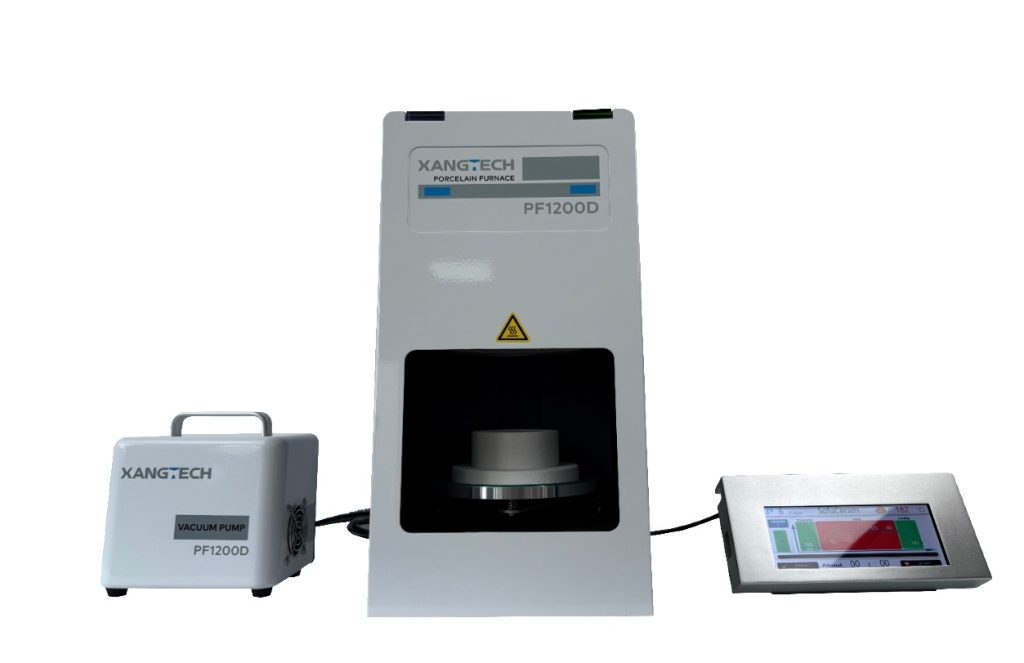

We built our porcelain furnaces with fresh ideas and ease of use in focus. XANGTECH PF1200D porcelain furnace is flexible. Bicurve mode shows the full crystallization process. Our setups use exact stepper motor drives for smooth work without shakes. Meanwhile, the small design allows fitting in tight spaces in labs or clinics.

XANGTECH advanced porcelain furnace has 99 adjustable programs for different ceramic types. This lets dental experts adjust firing details for any case—from basic veneers to tricky bridges.

Our simple touchscreen panels and USB links improve the user setup. They allow easy handling and ties with PC service plans. The voice alert feature, with clear and straightforward operation screens, makes user dealings simpler.

How Does XANGTECH Ensure Consistency and Reliability in Its Products?

Every XANGTECH furnace goes through tough quality checks before shipping. Automatic temperature tuning before each baking run makes sure heat readings stay true over time.

Our heating parts come from premium heat wire. This gives long use life and strong heat output. Whether firing one crown or a full set of veneers, our systems give steady results over runs with little upkeep.

Practical Applications of Porcelain Furnaces in Modern Dentistry

How Do Dentists Use Porcelain Furnaces During Restoration Fabrication?

Crown and Bridge Fabrication Workflows

In making crowns and bridges, dental ceramics often layer over metal or zirconia bases. These layers need several firings to form body features like dentin centers and enamel clearness. Each part—be it hidden layering or last glazing—calls for exact heat control from a solid porcelain furnace.

Veneer Customization Processes

Veneers need very slim yet beauty-focused layers of porcelain. Shaped by hand or CAD/CAM tools, they fire in steps to reach final color matches and surface shine. The glaze run at the close ensures smooth feel and glow. It closely copies natural enamel.

What Are the Benefits of Using a High-End Porcelain Furnace in Clinical Practice?

Using a top-tier porcelain furnace like ours brings several gains:

- Boosts patient happiness with better looks.

- Cuts down reworks thanks to strict quality checks.

- Raises lab output by trimming firing times without losing exactness.

- Handles varied material fits—from zirconia blocks to lithium disilicate pieces.

Maintenance Considerations for Long-Term Performance

How Can You Maintain a Porcelain Furnace for Optimal Functionality?

Routine Cleaning Guidelines

Steady cleaning of the firing area is vital. Buildup of bits or glaze leftovers can mess with heat spread and hurt ceramic quality. Check heating coils now and then for wear or harm signs.

Calibration and Software Updates

Do temperature tuning at suggested times to keep exactness. Our furnaces have auto-tuning tools that start before each run. Also, firmware updates through USB let you get new tools or better performance as they come out.

FAQ

Q: What is the purpose of vacuum in a porcelain furnace?

A: Vacuum helps eliminate air bubbles during firing, improving both strength and translucency of dental ceramics.

Q: Can I use one porcelain furnace model for all types of dental ceramics?

A: Yes, if the furnace supports programmable settings that accommodate different firing curves required by various materials.

Q: How do I choose the right porcelain furnace for my clinic or lab?

A: Look for models like those from XANGTECH that offer precise temperature control, user-friendly operation, reliable vacuum systems and customizable programs tailored to your workflow needs.