Understanding the Multilayer PMMA Block

What Is a Multilayer PMMA Block?

Polymethyl methacrylate (PMMA) is a man-made resin that has been used in dentistry for a long time for its visual qualities and simple handling. A PMMA block is a ready-shaped disc or chunk made from this stuff, planned specially for computer-helped plan and making (CAD/CAM) dental systems. These chunks get mainly used to make short-term tops, links, and other fake parts.

Multilayer PMMA blocks show a big step ahead over their one-layer matches. Their makeup includes many layers of PMMA material with slow shade changes that copy the natural slope found in true teeth. This plan gives better visual outcomes without the want for extra hand layering or coloring after cutting.

In difference, one-layer PMMA blocks are same in shade, which often calls for extra steps—like coloring or tinting—to reach a real-like look. This not only boosts work time but also brings change in the end outcome.

Why Is High Gloss Important in Dental Prosthetics?

The face shine of a tooth fix has a key part in how real it looks in the mouth. High shine copies the outer layer’s natural bounce, boosting the eye pull of fake teeth. More vital, it greatly affects patient joy by giving fixes that are not only useful but also eye-same from natural teeth.

Reaching a high-shine end also aids mouth clean. Smooth faces cut plaque build and make it simpler to wipe fixes, so boosting ongoing mouth wellness.

To get this shine, workers often use machine buff tools or put face coats. Still, the top PMMA blocks get planned to reach a high-shine end right from the cutting unit, cutting after-work time while giving top visual results.

Applications and Advantages in Dental Use

Where Are Multilayer PMMA Blocks Commonly Used?

Multilayer PMMA blocks are flexible stuff often used in varied short-term and check tooth uses. They suit well for making short-term tops and links during change stages of fake treatments. Their toughness and looks make them fit for full-bow fixes under quick load rules, where patient hopes for work and look are high.

Plus, multilayer PMMA blocks get used in making check wax-ups and cut guides. Their cut skill and build whole make sure exact copy of tooth shapes, turning them key tools in treatment planning and led cut.

What Makes Multilayer PMMA Blocks Suitable for CAD/CAM Dental Systems?

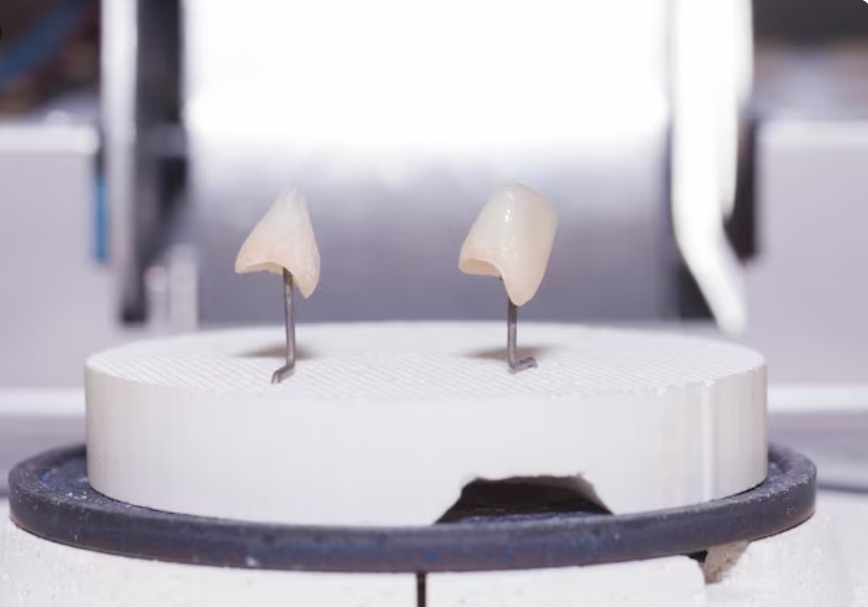

Digital flows in tooth work hang a lot on the steadiness and cut skill of stuff. Multilayer PMMA blocks get tuned for use with CAD/CAM setups due to their same build and layered setup. This lets exact cutting with top edge hold, letting tooth workers copy fine body details.

One main plus is their stand to chip during work. The slow layering not only backs visual flow but also strengthens build whole at layer joins, cutting the chance of breaks during cutting or use.

Their match with usual cutting machines makes sure workers can blend them smoothly into current flows, leading to useful make without losing on grade or looks.

How Do Color Gradients Enhance Aesthetic Outcomes?

Multilayer PMMA blocks show smooth shifts from neck to tip shades, copying the natural tint found in teeth. This slope cuts the want for hand coloring or layering after cutting—a way that can bring uneven or mistakes.

The in-built shade slope makes sure fixes have a more real look right from the machine. This not only boosts visual results but also betters patient take by giving fixes that mix naturally with next teeth.

Introducing XANGTECH and Its PMMA Block Solutions

Who Is XANGTECH and What Do They Offer in the Field of Dental Materials?

We at Nanyang Liandong Biotechnology Co., Ltd. bring more than 11 years of skill to the area of tooth lab stuff and gear. Our list covers a broad span of items such as zirconia chunks, glass pots, cutting bits, 3D checkers, and both one-layer and multilayer PMMA discs. Our aim is to send one-stop answers and top help to tooth experts around the world.

Our items get sent to more than 20 lands, gaining trust for their grade and sameness. Each item goes through strict grade check to make sure it fits tech rules needed for tooth labs.

What Are the Key Features of XANGTECH’s PMMA Block?

High Gloss Finish Without Additional Polishing Steps

Our multilayer PMMA discs give a built-in high-shine face right out of the cutting unit. This trait saves time in after-work and boosts flow usefulness while making sure fixes keep a buffed, real look.

Multi-layered Gradient Design for Natural Aesthetics

The fresh multi-layer build of multilayer PMMA discs adds to their top toughness. With natural shifts between layers, our discs copy the outer-inner build, letting workers make highly visual fixes without hand step.

High Dimensional Stability for Long-Term Use Cases

Multilayer PMMA discs send steady, top-grade results. They give fine size steadiness under changing mouth states such as temp shifts and damp. This cuts shrink or shape change during use, making sure lasting fit and work.

Biocompatibility and Safety Assurance Standards Met by XANGTECH Products

The top body-match of PMMA discs makes sure patient safety and ease. Our items get built for inside-mouth use with little chance of allergy hits or tissue rub.

Why Choose XANGTECH’s PMMA Block Over Conventional Options?

We mix fresh making ways with strict grade check to send always high-work stuff. Tooth labs trust our multilayer PMMA chunks for their ease of use, trusty cutting output, and visual results that fit current patient hopes.

Multilayer PMMA discs are also very flexible, fit for a broad span of tooth fixes. Whether you’re making short-term tops or check models, our answers give top worth across varied care cases.

Technical Considerations When Working with PMMA Blocks

How Should Technicians Handle Milling Parameters for Optimal Results?

Recommendations for Speed, Feed Rate, and Toolpath Strategy

To stop over-hot or tiny breaks during cutting, it’s key to follow suggested feed speeds and turn rates based on machine specs. Use sharp tools and tune tool path ways to keep face whole through the cutting step.

Post-Milling Finishing Tips to Maintain Surface Integrity

While our multilayer PMMA discs already give a high-shine end, using gentle buff wheels or shine rags can boost this more without harming the face. Skip rough scrapers that might dull or mark the stuff.

Are There Storage or Handling Precautions for PMMA Blocks?

Environmental Conditions That Affect Material Properties

PMMA stuff should get kept away from straight sun, too much warmth, or damp. Touch with UV light or lots of damp might change face traits or impact size exact over time.

Shelf Life Expectations Based on Manufacturer Guidelines

To keep best output, we suggest turning stock often and sticking to first-in-first-out keeping ways. Proper handling makes sure each chunk keeps its planned machine and visual traits through its use span.

FAQ

Q: What is the difference between a multilayer PMMA block and a single-layer one?

A: Multilayer PMMA blocks feature gradual color transitions that replicate the natural shading of teeth from cervical to incisal areas. Single-layer blocks have uniform color throughout, requiring additional staining or layering to achieve similar aesthetics.

Q: Can multilayer PMMA blocks be used for permanent restorations?

A: While multilayer PMMA blocks offer excellent aesthetics and durability, they are typically used for temporary restorations. For permanent solutions, materials like ceramics may be more appropriate based on clinical needs.

Q: How long do restorations made from XANGTECH’s PMMA block typically last?

A: Restorations made from XANGTECH’s multilayer PMMA block can last several months when used as temporaries. Their high stability ensures they maintain fit, color, and gloss throughout the intended duration before final prosthetics are placed.