Rotation axis working angle: A:360°B:-150°~+30°

Spindle speed: 0-60,000rmp/1800W

Power: 2.5KW

Rated working pressure: 4.5-7.5bar (anhydrous, oil-free)

Machining accuracy: 0.01mm

voltage: 220-230V

tool magazine: 21

Compressed air flow:120L/min

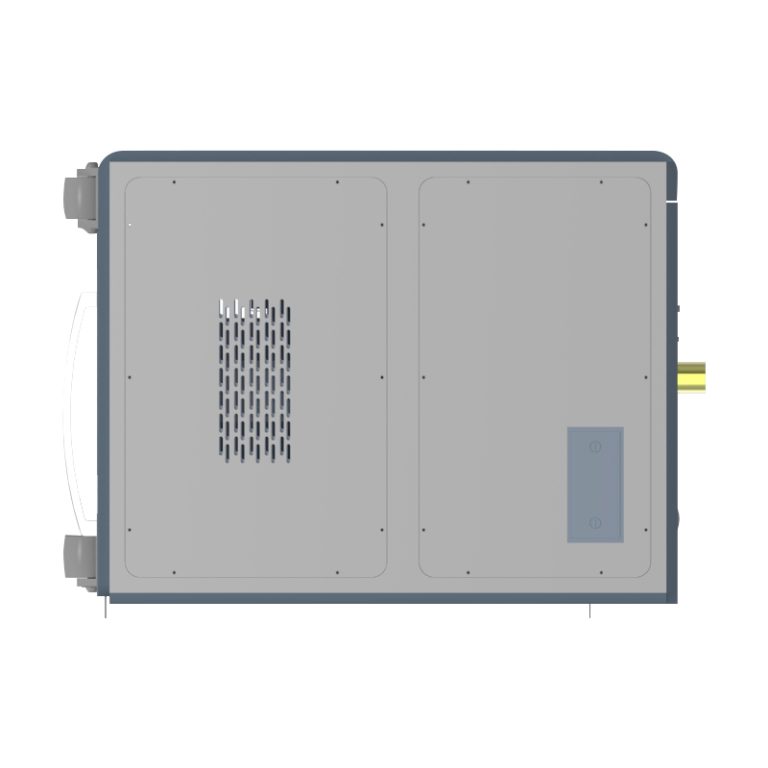

Size: 595*760*1650mm

Weight:360kg

Layout CAD Software: Open System

Drive:Full servo motor

Processing Method: 5 axis linkage,dry milling

Needle Specifications: Knife handle diameter 6mm automatic tool change

Machinable Material:Zirconia,Titanium disk,PMMA,glass csramics,titanium bar

XANGTECH RX-8H metal milling machine is an intelligent dental solution specifically designed for precision dental machining. Not only does it feature a vertical, comfortable, integrated design, but to guarantee precision and long-term stability from the ground up, our RX-8H milling machine utilizes top-tier international components in its core mechanical structure and control components. Within the milling machine, we’ve equipped it with a customized, high-computing intelligent control system. Combined with its proprietary high-speed data processing, micron-level precision control, and adaptive decision-making capabilities, it can meet customized machining requirements based on the characteristics of dental materials like titanium. Furthermore, it automatically generates optimal machining parameters and incorporates a multi-layered intelligent protection system (including overload protection, real-time temperature monitoring, and abnormal machining warnings) to comprehensively safeguard machine operation and machining safety.

By reducing operational complexity and increasing the automation level of the machining process, RX-8H dental milling machine can achieve fully unmanned operation. XANGTECH RX-8H dental milling machine is not only equipped with a large-capacity intelligent 21-tool magazine, but also allows for a single-button start to trigger the entire machining process. RX-8H metal milling machine even automatically performs tool changes, precise tool length detection, and dynamic tool posture correction, minimizing auxiliary labor time and improving the efficiency of batch processing. Our metal milling machine’s ultra-high-speed precision spindle, with a maximum speed of 60,000 rpm, combines powerful cutting power with micron-level operational stability. This allows it to easily and efficiently cut high-hardness dental materials like titanium discs while maintaining the surface finish and dimensional accuracy of products such as crowns and abutments. To meet the diverse needs of dental processing scenarios, RX-8H metal dental milling machine has highly flexible adaptability: it can customize and match exclusive processing strategies according to the characteristics of different dental materials, such as pure titanium, titanium alloy, diamond ingot, resin wax blocks, glass ceramics, prefabricated abutments, and personalized abutments. XANGTECH detnal RX-8H metal milling machine can also fully cover the personalized production needs of different users such as dental clinics and denture processing factories according to different crown types such as full crowns, bridges, and implant abutments, providing core dental equipment support that combines precision, efficiency, and flexibility for high-end dental manufacturing.

1. Efficient and stable metal cutting equipment.

2. 21-inch tool magazine with automatic tool changer.

3. B-axis angles up to +35° and -91°.

4. Automatic tool life and wear detection.

5. One-touch automatic calibration.

6. Abutment, implant bar and implant bridge processing solutions.