Understanding the Basics of Dental Furnaces

What’s a Dental Press Furnace?

A dental press furnace is a super handy tool used in dental labs and clinics. It works as both a press furnace and a ceramic furnace, making it a go-to for crafting top-notch dental fixes like crowns, bridges and veneers. This two-in-one setup lets technicians do pressing and ceramic firing in one machine, which saves time and effort.

The device mixes smart design with cool tech to make things efficient, precise and easy to use. It works great with materials like lithium disilicate and zirconia, so you get restorations that are tough and look awesome.

What’s a Dental Porcelain Furnace?

A porcelain furnace is a must-have lab tool for making dental restorations. It heats up dental crowns, veneers and bridges made of porcelain or ceramic to a high temp to fuse them into a solid piece. These furnaces are built just for firing ceramics like feldspathic porcelain or glass ceramics to get their final hardness and see-through look.

Porcelain furnaces have key parts like a heating element, temp controller and a chamber to hold the restoration during firing. Some fancy models have vacuum features to clear out air bubbles during the process, which boosts the quality of the results.

How Do These Furnaces Fit into Dental Workflows?

Both types of furnaces are super important for fixing teeth. Porcelain furnaces churn out high-quality restorations that are strong, long-lasting and nice to look at. They’re usually used after milling or hand-shaping to lock in the restoration’s final traits.

Meanwhile, the dental press furnace handles both pressing and ceramic firing, so you don’t need two machines. It shapes things precisely and makes sure the material is nice and dense. This combo cuts down on handling time between steps.

What’s the Difference Between a Press Furnace and a Porcelain Furnace?

Are the Heating Systems the Same?

Both furnaces use high-heat chambers with controlled temp settings, but there’s a slight difference. Press furnaces often have a setup for applying pressure during the heat cycle, which is key for working with pressable ceramics like lithium disilicate ingots.

Porcelain furnaces focus more on spreading heat evenly without pressure. XANGTECH advanced porcelain furnace includes a durable quartz spiral for efficient heat distribution, which makes ceramic firing super consistent.

How Do Their Uses Differ in Dental Labs?

Material Fit and Use Cases

Dental press furnaces work with a bunch of dental ceramics like lithium disilicate and zirconia, making them great for pressed crowns, bridges, inlays, onlays and veneers. The pressure feature ensures dense restorations with hardly any holes.

Porcelain furnaces are best for sintering or layering feldspathic porcelains or glass ceramics over frameworks. Ceramic combination furnaces are designed to fire and press ceramic restorations, but traditional porcelain-only models stick to firing tasks.

Workflow and Efficiency

By eliminating the need for compressed air, it not only reduces operational complexity but also ensures consistently excellent results across a range of applications. This makes press furnaces more self-running compared to traditional porcelain models that might need external vacuum systems.

Porcelain furnaces usually offer more customizable programs for specific heat curves, which is key for multi-layered build-ups. The XANGTECH porcelain furnace boasts 99 customizable programs alongside built-in options, providing flexibility in lab workflows.

Which One Has Better Temp Control?

Both can have awesome control depending on how they’re made. However:

XANGTECH advanced фарфоровая печь includes high-quality temperature automatic adjustment, keeping errors within +/- 1°C. It also auto-calibrates before each use—a big deal when working with sensitive stuff like glass ceramics.

Press furnaces need tight control too but often focus just as much on pressure regulation. The XANGTECH press furnace guarantees high edge precision while also maintaining a low probability of failure, showing it’s reliable even under tough conditions.

Choosing the Right Furnace for Your Practice or Lab

What Should You Think About Before Buying?

Type of Restorations You Make

If your practice often uses pressable materials like lithium disilicate ingots or focuses on full-contour monolithic crowns that need compacting under heat, a press furnace is the way to go.

For labs working on veneering metal frameworks or layering feldspathic porcelains by hand over zirconia substructures, a dedicated porcelain furnace is better.

Budget, Space and Output Needs

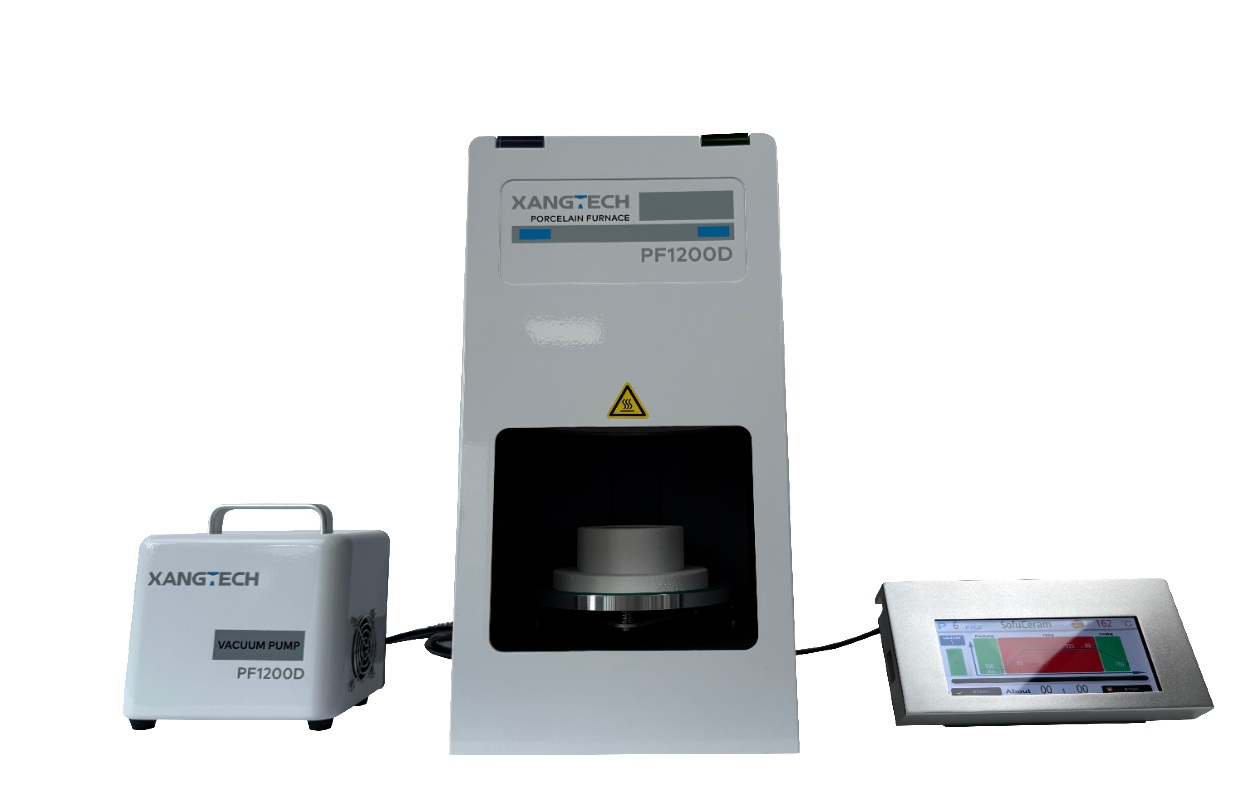

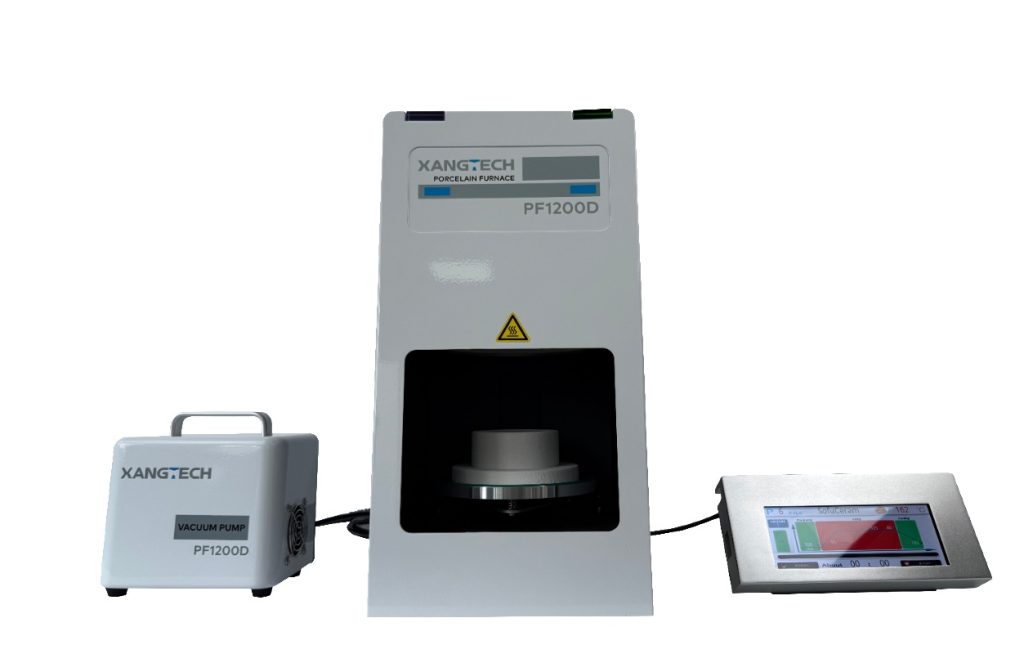

Space-saving designs are a big deal in smaller labs. XANGTECH’s porcelain furnace combines a compact design with exceptional functionality, making it great even where space is tight.

If your lab handles all kinds of cases or has big output needs, a combo model or owning both types might give you better bang for your buck by streamlining your workflow.

Should You Have Both Furnaces in One Lab?

Yup—especially if your lab does a wide range of restorations, from pressed front teeth fixes to layered back teeth units. Having both lets you tailor processes to the material without getting held up by equipment limits.

Some modern press furnaces do double duty too. Versatility is at the heart of our press furnace equipped to handle both pressing and porcelain functions. This can cut equipment costs while boosting what you can do with one machine.

Meet XANGTECH: Top-Notch Solutions for Dental Ceramics

Why Pick XANGTECH for Your Dental Lab?

With over 11 years of know-how delivering trusty lab materials worldwide, we at XANGTECH focus on all-in-one solutions tailored for dental pros globally. All products are produced in strict accordance with technical standards, ensuring consistency across every application—from materials to machinery.

Our mission is simple: help labs work better with innovative tools backed by solid support, including network-based tech help during warranty periods.

Features of XANGTECH’s Dental Press Furnace

Our XANGTECH dental press furnace stands out because it doesn’t need compressed air—making setup easier and cutting maintenance costs. This advanced furnace stands out for its ability to operate without the need for compressed air guarantees high edge precision ensures dependable performance over time.

It handles both pressing cycles with ingots and standard ceramic firings, making it super flexible for different case needs without skimping on quality or reliability.

Features of XANGTECH’s Dental Porcelain Furnace

Our porcelain furnace nails accuracy with auto-calibration before every cycle and a smart temp control system accurate within ±1°C. This state-of-the-art device combines a compact design with exceptional functionality smooth jitter-free operation thanks to its precision stepper motor drive ensures consistent results every time you fire restorations—from simple copings to complex layered units.

With USB connectivity enabling PC integration plus 99 customizable programs—we’ve built this unit around flexibility so you can tailor workflows exactly how you need them while monitoring status indicators in real-time during operations.

Часто задаваемые вопросы

Q: Can I use lithium disilicate ingots in both types of furnaces?

A: While both can technically process lithium disilicate under specific conditions, it’s recommended to use a press furnace due to its pressure-application capabilities which ensure optimal density during pressing cycles.

Q: How often should I calibrate my porcelain furnace?

A: Our XANGTECH porcelain furnace automatically calibrates before each roasting process, ensuring consistent performance without requiring manual intervention every time.

Q: Is there any maintenance required for these furnaces?

A: Yes—but minimal when using our systems. The XANGTECH press furnace is engineered for low maintenance, translating into reduced downtime and cost savings over time.

Q: Can I integrate these units into my existing digital workflow?

A: Absolutely! Our devices support USB connectivity, facilitating easy integration with PC service programs so you can sync them seamlessly into digital production pipelines including CAD/CAM systems.